Heat resistant cast iron in the form of ingots

Heat resistant cast iron in the form of ingots

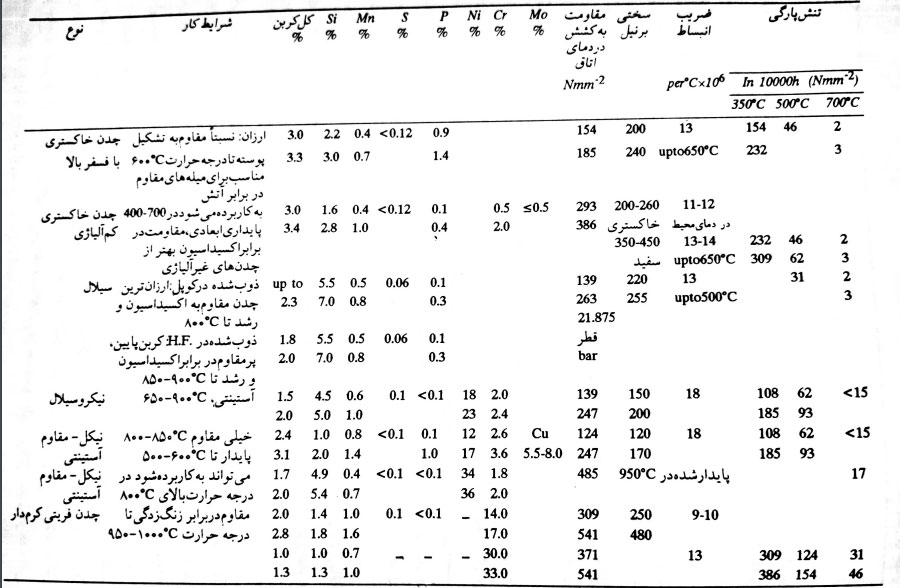

For casting cast iron parts, cast irons required to study critical and sensitive engineering applications at high temperatures must demonstrate good mechanical properties at high temperatures, structural stability and oxidation resistance. Non-alloy gray cast irons can be satisfactorily used up to about 500 ° C as heat-resistant nets, thermal backing and lattice rods. Additives with small amounts of cr and mo modify their engineering use in critical situations.

The use of graphite gray cast iron with high thermal conductivity can minimize thermal stresses. For example, in ingot molds on the surface between the metal and the mold along the ingot, the local temperature is equal to 800-900 degrees and the difference in mold temperature can exceed 300 degrees and cause severe heat cycle. Damage and damage. It manifests itself in the form of large and deep cracks, which are due to oxidation and changes in structure.

Ferrite-perlite substrate is austenitic in this state and produces finer perlites in any form. Oxidation is advanced on internal surfaces and is followed by decarbonization and scaling. By alloying with mn, the life of the mold can be increased by about 20-40%. In this case, perlite is converted to ferrite + free carbon (this free carbon is absorbed by graphites and the ground becomes only ferrite), but perlite is in the form of spherical ferrite + cementite.

Another method that has been used recently is the use of pressed graphite cast irons, which with a combination of the characteristics mentioned in the mold table, make stronger gray cast iron molds and have greater resistance to bends and curvature better than cast iron molds with chrome graphite. Has.

Spherical graphite cast irons have low thermal conductivity compared to cast iron and layered graphite and have high tensile strength. Although the final grade of spherical graphite with a high thermal gradient increases the thermal stresses, these spherical graphite molds are much more resistant to cracking. In any case, their yield point and resistance to high thermal stress is not enough.

Leave a Reply

Want to join the discussion?Feel free to contribute!