What is precision casting?

What is precision casting? This is the topic we want to explore in this article.

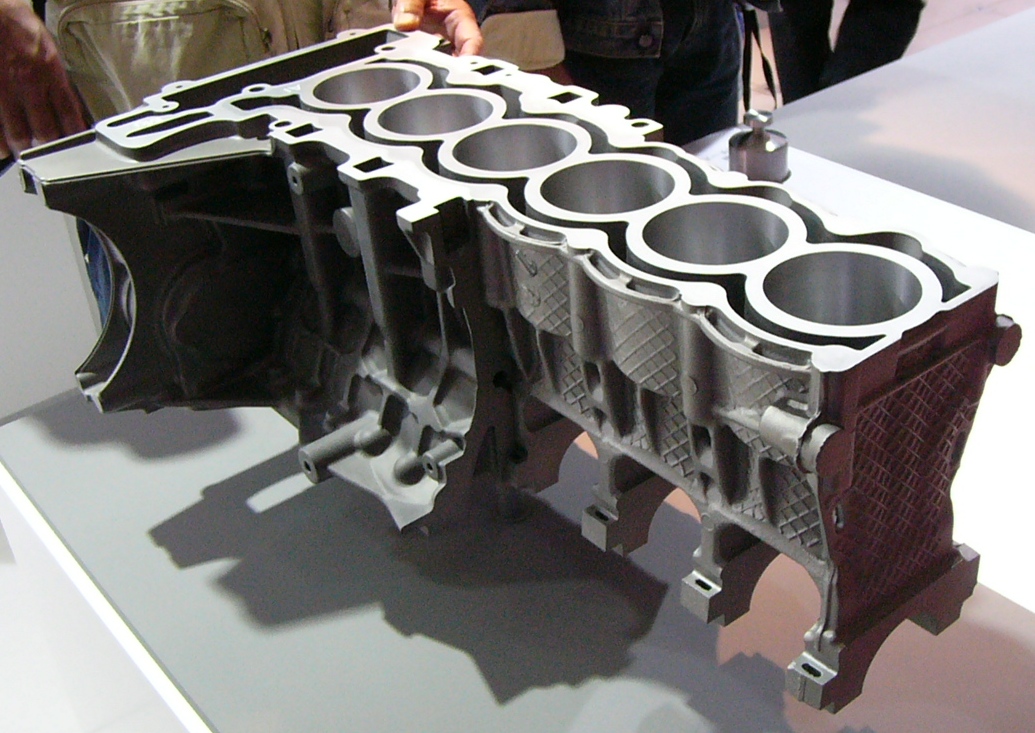

Casting processes Steel and cast iron parts are widely used in the manufacturing industry to produce products and components with complex shapes. Although there are different types of casting processes, most of them involve pouring a liquid such as molten metal. Or plastic heated in the center of a hollow mold that, after cooling the liquid material, the product is removed from the mold. Precision casting is a unique casting method that has been increasingly used in recent years. Is.

The defining characteristic of precision casting is that it first covers the mold with liquid refractory material, then the mold is filled with liquid material.

Advantages of precision casting

Precision casting offers several significant advantages. Using this casting method, high quality products and parts can be created. Also, this production method can be used to produce very complex parts.

In addition, precision casting supports a variety of materials, some of which include stainless steel, brass, carbon steel, aluminum, glass and plastic. Aluminum and copper alloys are the most common types of metal used in this casting process. Precision casting is a very efficient process because it creates minimal waste compared to other casting processes.

The precision casting process produces parts with superior dimensional accuracy, and parts are often produced without secondary machining.

On the other hand, this method of casting steel parts has certain disadvantages, one of which is its high cost. Precision casting is more expensive than other casting processes, which some manufacturers may use. However, the benefits often outweigh the costs.

There are significant differences between the two methods used to make metal parts, precision casting and sand casting. Precision casting is often much more expensive than sand casting.

Precision cast parts include medical equipment, gears, jewelry and many other parts with intricate geometry.

For more information about this process or to determine if this method is right for your application, please contact us.

Leave a Reply

Want to join the discussion?Feel free to contribute!